![]()

Turn-Key Systems

Navionics Research Inc. offers a broad range of in-house experience in telemetry system

integration, installation, and commissioning. Leveraging the most advanced

industrial, PC-compatible computer hardware platforms available, and supported by complete

documentation, we can provide an easy-to-use turnkey telemetry and control solution

to your rural water or wastewater district.

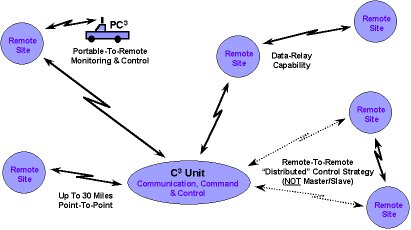

Distributed Control

One of the most prevalent telemetry strategies in the water and wastewater industries is the "Master-Slave" scheme.

In a "Master-Slave" network, all remote RTU's report their status to a central computer

or PLC, which then returns the control

commands. However, if the central computer/PLC is down for any reason (e.g. power outage or repairs), the entire control

network stops functioning. This can be catastrophic for rural water or wastewater districts which are often spread out

over hundreds or even thousands of square miles.

Navionics Research specializes in the more fault-tolerant "Peer-To-Peer" telemetry and control systems. In a "Peer-to-Peer" network, all RTU's operate in a

smart, stand-alone mode at all times.

For example, in 1998 a tornado ripped through the main office of a

rural water company outside Centralia IL, after which their C3 SCADA Server was without

power for 3 days. However, while the water company was busy rebuilding

the office, their remote water towers and pump stations — which did have power — continued to operate as normal, keeping

all customers supplied with water. In the face of a natural disaster, their

SCADA system was one thing

they didn't have to worry about. After all, the measure of a fault-tolerant system is how well it operates under

less-than-ideal conditions.

Wireless Advantages

You'll begin to receive the payoff benefits of your new Navionics wireless telemetry and control

system beginning with the first day of operation. Our customers report a drastic reduction in the amount

of mileage spent monitoring their remote sites. And when there is a problem — such as a sump pump failure

in an underground pump station — the telemetry alerts the utility personnel immediately

and before the problem escalates.

With centralized and automated history charting on the C3 SCADA Server operator

interface, our customers invariably gain new insights into the

hydraulic dynamics of their system. Finally, because we use the most

dependable, non-proprietary wireless data communication equipment and

CRC checksum algorithms

available, our customers experience a much greater reliability than

leased-line and cellular-based telemetry systems — and without the recurring charges.

Industrial, PC-Compatible Hardware

Navionics' core computer platform which we have selected is perhaps the most widely-accepted electronic

standard in history: the IBM PC-compatible architecture. Leveraging the expandable computing and I/O power

inherent in the PC-compatible architecture, the Navionics Research WiSTAR system represents the cutting edge of programmable

industrial control. We provide full product documentation and

manuals in support of this hardware.

Control Sub-System

The Navionics Research RTU is an expandable, field-programmable industrial controller.

Because the RTU is "software-intensive", the overall control system complexity is vastly

reduced - featuring far fewer auxiliary devices along with simplified installation and wiring

procedures. And as your control requirements evolve over time, additional analog, digital,

pulse, and fieldbus inputs and outputs can be easily added, along with the programming logic needed to control

them. In certain cases, logic upgrades have been sent via UPS or Fedex from our facility to

the customer.

Because each RTU has a single processor, the control and wireless communication processes are very

tightly integrated. For example, at one rural water company, a

booster pump station bases its pump control decisions upon the water level in the remote

elevated tank. However, when an extended power outage at the tank exceeded its battery backup reserve in June of 1999,

the pump station had to "fly blind" for approximately 8 hours. Because the control process was always

"aware" of the communication status, the pump station was able to automatically fail over smoothly into

a "local pressure" control strategy — and thereby maintain water storage in the system.

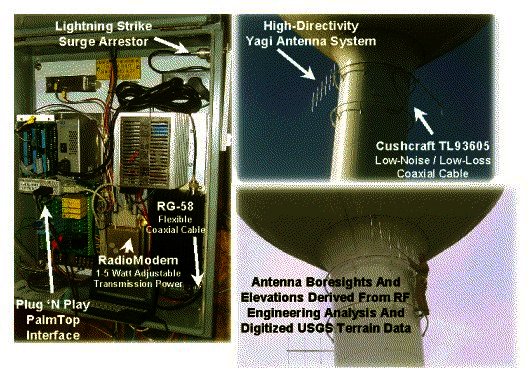

Communication Sub-System

The Navionics Research RTU was designed for wireless communications. Difficult

terrain is easily overcome with built-in repeating capability — and the adaptive re-routing

algorithm can alter communications paths on-the-fly to compensate for a missing repeater. Channel

usage is kept to a minimum by a judicious combination of "polling" and "report-by-exception".

And by leveraging the most modern CRC error-detection communication technology available, data errors and

interference problems are completely eliminated.

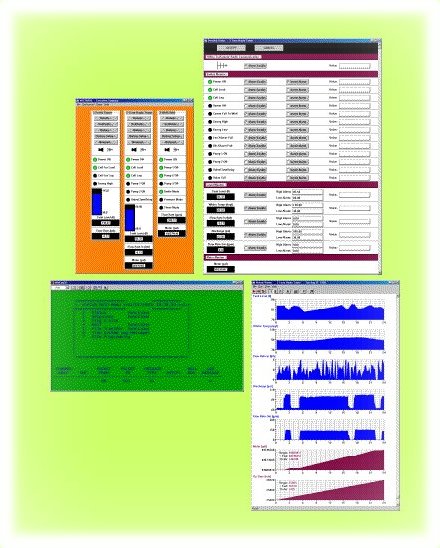

Graphical Operator Interface

With its innovative C3 (Communications, Command, & Control)

Telemetry Server and Graphical

User Interface (GUI), Navionics Research is a regional leader in the wireless telemetry and control interface arena. And thanks to the many customer

suggestions over the years, the Telemetry Server offers a wealth of operator-oriented features.

For example, even though the C3 Server has full remote-control and setpoint modification capabilities,

it is not a "Master-Slave" design. Navionics has always maintained the integrity of its "Peer-to-Peer" strategy.

And changing or adding an "RTU site" is a snap - no software rebuilds are required.

Another unique feature is the C3 Server's ability to automatically archive history data on-the-fly. The end-result

is that the C3 Server has the capacity to hold up to 200 years of history data, as opposed to many competitive systems

which feature only a capacity to hold 30-60 days of history. And being able to view history charts has proven

to be such a useful feature that Navionics provides its remote

access client software free-of-charge to all of our customers

so that they can share performance data with their consulting engineers.

When something goes wrong in the field, the C3 Server alerts the operator with an audible alarm, as well as a

flashing graphic. If the operator is away from the computer, then the

Server sends a

descriptive message to his smartphone — detailing the exact location and nature of the problem.

Another revolutionary component of our system is the "Portable C3 GUI",

a notebook-and-radio-based graphical operator interface. Navionics

implementation is both powerful and unique. For example, when it is

staged in the operator's vehicle, the software automatically detects the vehicle's location and modifies

the communication relay paths accordingly. In this manner, the operator is able to maintain a continuous telemetry

data link to all RTU sites while working in the field. Also, the operation is completely hands-free, and it even

works while the vehicle is in motion.

Radio Path Analysis

Before a project is started, the exact coordinates of the future telemetry sites are obtained from

either a GPS survey or from the customer's engineering data. Then, the proper selection of radio

frequency band, transmitter power levels, antenna heights, antenna gains, and antenna boresight angles

is achieved through a pre-job computer radio simulation.

This simulation, which takes into account a

terrain model imported from the digitized US Geological Survey database, ensures that any obstructions

are located and overcome early in the design phase of the project. Since we do the homework up front,

our telemetry systems provide solid inter-site communications "right out of the box".

Economical Point-to-Point Telemetry

As an addition to our more comprehensive SCADA system offerings, we are proud to introduce the low-cost and high-quality TeleTransducer™ System!

How can both high-quality and low-cost be achieved simultaneously? –

By utilizing select components that are recognized throughout the industry as top-of-the-line,

while achieving low-cost through the simplicity of an astonishingly low parts count.

Brochure (Click Here For

Details)